Press Releases

Leather: A Renewable Material

November 6, 2023

Biobased Materials Support Circularity Goals

Leather starts with a cattle hide, which is a natural material and 100% biobased. By using renewable finishes in the leather making process the level of renewability of the material remains high, often as high as 95% for a finished automotive product. Even in the case of using less sustainable chemicals or a heavy amount of finishing, the renewability level of leather will not likely go below 80%. In comparison to alternatives, this is very high, since most alternatives contain a high level of fossil-based materials1 (e.g., plastics) and largely score lower than 50% in renewability.

Genuine Leather vs. Alternative Materials

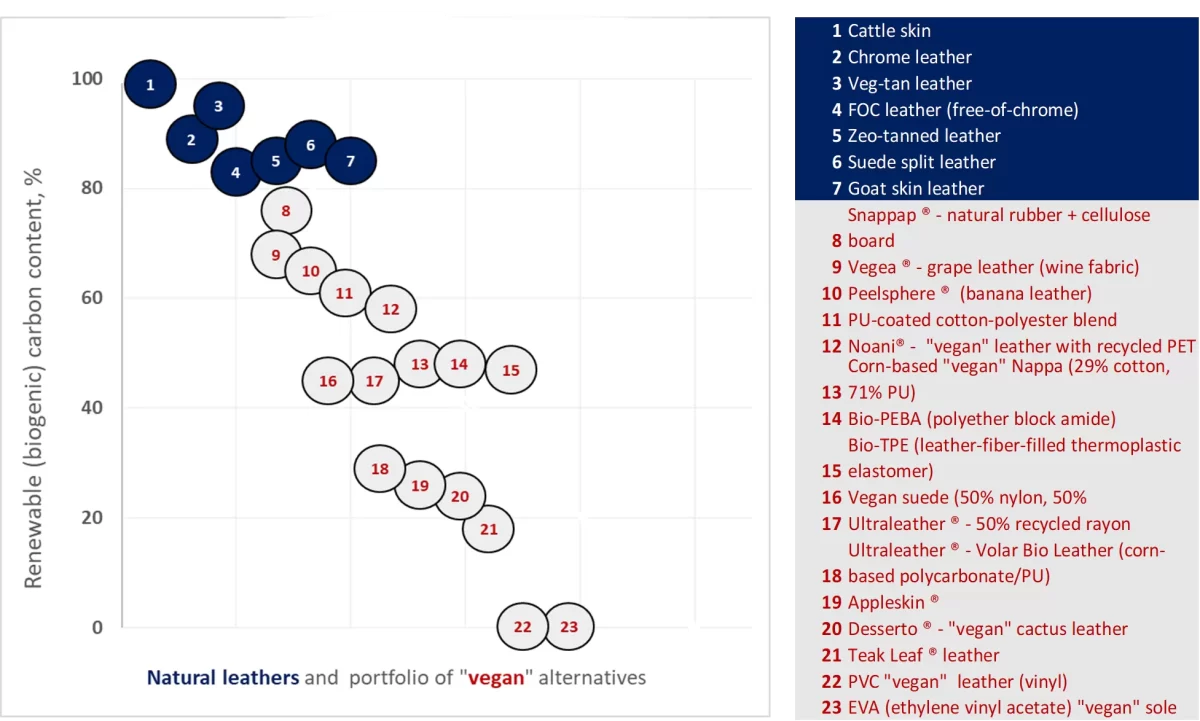

The figure below shows the comparisons of bio-based carbon contents of leathers with various manufacturing recipes (bio-based vs traditional petro-based) and on various types of ‘bio-based alternative materials’ such as ‘cactus leather’ and AppleSkin.

The data presented in Fig.1 clearly demonstrates the high bio-based nature of leather. Even with traditional petroleum-based coating polymers, finished leather still presents a typical bio-based carbon content around 80%. Leathermaking recipes can be further optimized, which Pangea often does, providing a range of 85-95% bio-based end-product, without impacting the performance of the automotive leather. By contrast, the self-proclaimed ‘bio-based alternative materials’ typically present a much lower bio-based carbon content, as well as weaker durability and performance, often below automotive standards.

The biogenic carbon cycle centers on the ability of plants to absorb and sequester carbon. The more renewable content (biogenic carbon) a material has, the better it fits into a circular economy. Carbon can either be classified as biogenic or fossil, with the former assigned to carbon stored in, sequestered by, and emitted through organic matter. In fact, fossil carbon forms when living matter dies and is deposited on the ground.

Wait-what does ‘bio-based’ actually mean?

‘Bio-based’ specifies the source of materials that contain this biogenic carbon. It refers to materials that are made from renewable resources and consist at least partially of biological materials. Think of plant fibers, sugar(s), microorganisms, orproteins2.

Whilst fossil fuel-based materials disrupt aggregate carbon to the natural cycles on earth, bio-based materials are actually essential parts of our natural cycles and do not add to the existent carbon levels. Meaning: by using bio-based resources we are not depleting our resources.

The effect of high bio-based content in leather

Araw hide is renewable in and of itself and intrinsically biodegradable. Depending on the leather making process, including the right chemicals and tanning agents, biodegradability and composability levels of the processed leather can be improved. When the leather substrate itself has a high renewable content, this also means the waste streams and residues (clippings, shavings) from its manufacturing process will be more bio-based and can be re-used, recycled, repurposed, or better fit for its end-of-life disposal. Often, Pangea leather shavings and scraps are re-used in other industries such as consumer goods, cosmetics, agriculture, and bio-polymers3.

Automotive manufacturers, designers, and engineers alike, are often searching for what is new and innovative in process and material choices. However, based on an abundance of research, the most sustainable options lie in the most optimized bio-based materials. Even the USDA with its BioPreferred Program will certify almost any product that is at least 25% bio-based, so the certification does not hold much weight in our view because of such low level of “renewability”. Being of bio-based nature with adequate composability would support full circularity of leather. As our community chooses more bio-based products, it’s important to take advantage of the leather legacy.

About Pangea

Pangea is a global leather supplier to the world’s leading automotive brands, providing material solutions that drive the future of natural interiors. Headquartered in Rochester Hills, Michigan. Pangea serves its customers on four continents with nearly 3,500 team members. For more information, visit www.pangeamade.com, and follow us on LinkedIn (@Pangea-made).

Media Contact

Jacquelyn Smith, Pangea

248-436-2200

Footnotes

1. https://ecocult.com/list-vegan-leather-alternatives-ranked/

2. https://ecochain.com/blog/is-biobased-always-sustainable/#:~:text=Whilst%20fossil%20fuel%2Dbased%20materials,aren’t%20depleting%20our%20earth.

3. Pangea shavings are currently recycled into biopolymers via manufacturers like Stover, Lefe, Apelsa

4. https://www.biopreferred.gov/BioPreferred/faces/pages/ProductCategories.xhtml